Power Transformer Core Components

When installing, we need to ensure that the clamping device remains rigid and secure to prevent any failure during vibration.

Step-lapped power transformer cores during manufacturing when stacking silicon steel sheets Compared to core types, the shell type is considered a more versatile option because it has a very wide range of core requirements for power transformers depending on the arrangement. The magnetic core mechanically acts as the main structure of the transformer, reducing the amount of external clamping.

Power transformer core during assembly while stacking silicon steel sheets, focusing on the cutting edge of the center leg

All necessary insulating parts cleats for yoke clamping and columns for winding support are manufactured according to customer requirements. These cores are mounted on stacking tables. Stacked on guide bolts with the most precise leg support settings at center distances, geometric measurements are maintained and air gaps are minimized.

Why are core-type transformers less efficient than shell-type transformers?

The core type is considered to be less efficient than the shell type because a very small amount of magnetic flux leaks out of the core during operation.

What are the basic structures required for a power transformer?

The basic structure of any power transformer is exactly the same as any large transformer. All power transformers, regardless of their overall size, have three main parts: the high and low voltage windings, and the magnetic core.

Installation And Basic Structure Of Core Components Of Power Transformers

Recommended Products

-

View More >>

View More >>

Non-Toroidal C-Type Cut Amorphous Nanocrystalline Cores

Industry: Amorphous Nanocrystalline Core

-

View More >>

View More >>

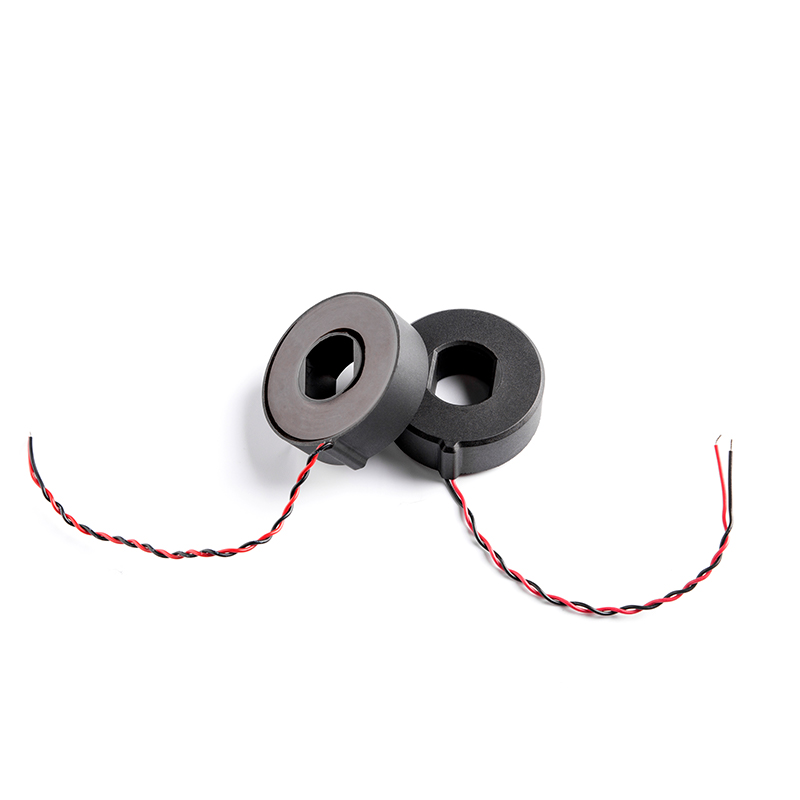

EHC-VCT Series for Power supply

Industry: Current Transformer

-

View More >>

View More >>

Transformers Cores Amorphous Nanocrystalline Cores

Industry: Amorphous Nanocrystalline Core

-

View More >>

View More >>

Amorphous Nanocrystalline Inductor Cores

Industry: Amorphous Nanocrystalline Core

-

View More >>

View More >>

CTS Series Terminal High Precision Amorphous Nanocrystalline Current Transformers

Industry: Current Transformer

-

View More >>

View More >>

Rectangular hysteresis loop Cores

Industry: Amorphous Nanocrystalline Core

-

View More >>

View More >>

High Linear Current Transformers

Industry: Current Transformer

-

View More >>

View More >>

Common Mode Choke Amorphous Nanocrystalline Inductors

Industry: Amorphous Nanocrystalline Inductors

English

English 中文简体

中文简体 Deutsch

Deutsch 日本語

日本語