In the ever-evolving world of electronics, power efficiency and miniaturization remain at the forefront of innovation. As devices become smaller and more powerful, engineers are constantly seeking materials and components that can deliver high performance while minimizing energy loss. Enter amorphous nanocrystalline inductors—a game-changing advancement in magnetic component technology.

Amorphous nanocrystalline materials combine the best of two worlds: the superior magnetic properties of nanocrystalline alloys and the structural flexibility of amorphous metals. These materials are produced by rapidly cooling molten metal alloys, which prevents the atoms from forming a crystalline structure. This results in a unique combination of high permeability, low core loss, and excellent thermal stability—qualities that make them ideal for use in inductors.

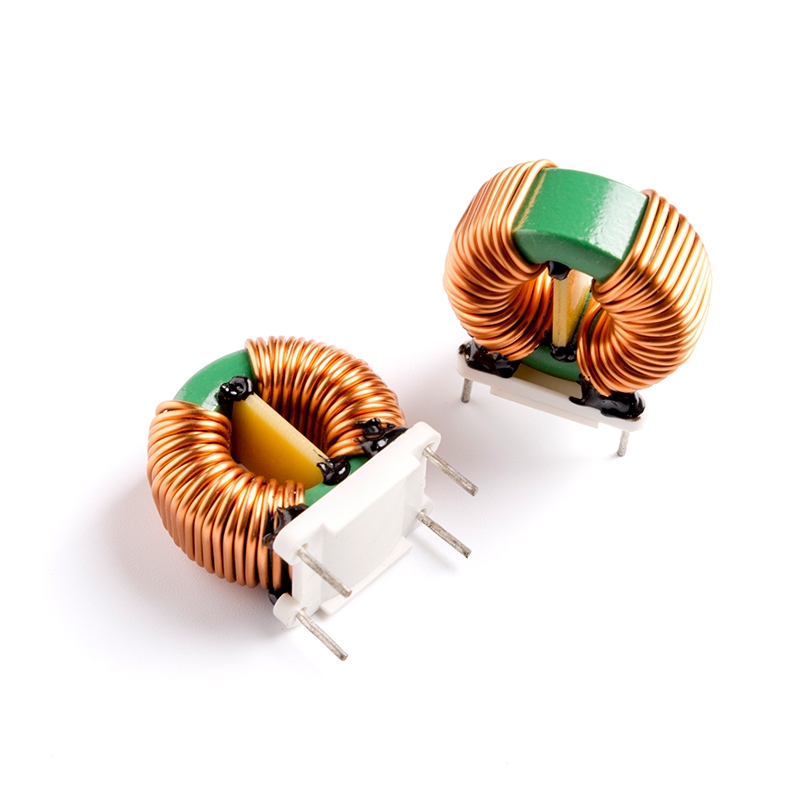

Inductors play a critical role in electronic circuits, particularly in power conversion systems such as inverters, converters, and transformers. Their primary function is to store energy in a magnetic field and regulate current flow. Traditional ferrite or silicon steel inductors have served this purpose well, but they come with limitations. Ferrite cores, for instance, can suffer from reduced efficiency at higher frequencies, while silicon steel cores are prone to significant energy losses due to eddy currents and hysteresis.

Amorphous nanocrystalline inductors address these shortcomings head-on. Their ultra-fine grain structure minimizes energy losses, making them highly efficient even at high frequencies. Additionally, their compact size allows designers to create sleeker, lighter devices without compromising on performance. This makes them especially appealing for applications in renewable energy systems, electric vehicles (EVs), and telecommunications infrastructure.

One standout application of amorphous nanocrystalline inductors is in EV charging stations. These systems require robust, efficient components capable of handling high-frequency operations and delivering reliable power transfer. The low core loss and high saturation flux density of nanocrystalline inductors enable faster charging times and improved overall system efficiency, contributing to the global push toward sustainable transportation.

Another promising area is in data centers, where energy efficiency is paramount. Power supply units equipped with amorphous nanocrystalline inductors can significantly reduce energy consumption, leading to cost savings and a lower carbon footprint. This aligns perfectly with the growing emphasis on green technologies across industries.

As demand for smarter, greener electronics continues to rise, the adoption of amorphous nanocrystalline inductors is expected to accelerate. Manufacturers are already investing heavily in scaling production and refining fabrication techniques to meet this surge in demand. With their unparalleled combination of efficiency, durability, and compactness, these inductors are poised to redefine the standards of modern electronic design.

English

English 中文简体

中文简体 Deutsch

Deutsch 日本語

日本語

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>