At the heart of every power monitoring device is a CT Current Transformers (CT). If you're wondering why you should use them or how they work, here's a quick review of the basics of AC CT.

Current sensors are used to measure the current on a circuit. They work by converting the magnetically induced current of the conductors placed on them into proportional currents flowing through the CT conductors. They allow the power meter to measure the current on the circuit, which would overload the meter if the current was measured directly. If the power supply is to be monitored, a CT is required.

Current sensor type

There are two main types of CT.

Solid CT forms a permanently closed core. Installing a solid core CT requires breaking the conductor to pass it through the CT core (imagine a string going through the eye of a needle). The benefit of solid CTs is that they are generally cheaper and more accurate. They are most commonly used for new installations.

Split Core CTs have a "split" in the core, allowing the CT to be opened and placed around the conductor without disconnecting the conductor or interrupting the wiring. Split core CTs can be more expensive, but their convenience often outweighs their cost when dealing with retrofit installations.

current rating

Most CTs are marked according to their current rating. It is important to use a CT rated as close to the actual current as possible to obtain the accuracy of the CT at the lowest possible load.

Most CTs start to become accurate at 5-10% of their rated capacity, depending on their accuracy class (see Accuracy below). At lower loads, some CTs can become very inaccurate.

Most CTs maintain an accuracy of 120-130% of their rated capacity. Beyond the maximum ratings, the CT will "saturate" and the measurement accuracy will rapidly degrade. Overloading the CT also risks damaging it.

Choosing the best current rating for a CT should be based on the expected minimum, average and maximum loads. Consider a circuit with a 100 amp circuit breaker. If a CT with a nominal current rating of 70A and an accuracy class of 1.0 (84A maximum capacity) is used, the CT will be accurate to a 7A load, while a 100A nominal rated CT will be accurate to a 10A load. This is only necessary when the circuit is lightly loaded. Anytime a circuit encounters 84A or more, it cannot be measured accurately with a 70A CT, and the CT may be damaged.

accuracy

CTs are available in a variety of accuracy grades, with errors ranging from 0.1% to 5%. A typical CT has an accuracy of 1% (called class 1.0). Accuracy will be expressed over a specific load range. For a 1% rated CT, the accuracy is expressed over a measurement range of 10% to 120% of the CT's rated current. Therefore, a class 1.0 CT with a nominal current rating of 100 amps will provide 1% accuracy over the current range of 10 to 120 amps.

physical size

Note the inner diameter of the CT. This describes the size of the opening inside the CT. If you try to use a CT with an inner diameter that is too small, it will not fit around the conductor. If it's too big, it won't be as accurate.

output

The CT itself will have a current output, such as 1A or 5A, which represents the output value of the CT's nominal rating. Shunt CTs use internal resistors (shunts) to generate a voltage output such as 0.33V and a current output. Current output CTs can generate abnormally high and dangerous voltages when wires are disconnected and the CT is installed on a live conductor. Therefore, shunt CTs have safety advantages and are preferred in higher power circuits.

Install

One of the most common mistakes in CT installations is the wrong orientation. The CT needs to be oriented with a specific side facing the source (away from the load). CTs often have indicators to help with proper positioning. Wrongly oriented CTs can result in negative power readings.

Current Sensors: Split Core, Solid Core, And Why You Should Care

Recommended Products

-

View More >>

View More >>

Non-Toroidal C-Type Cut Amorphous Nanocrystalline Cores

Industry: Amorphous Nanocrystalline Core

-

View More >>

View More >>

EHC-VCT Series for Power supply

Industry: Current Transformer

-

View More >>

View More >>

Transformers Cores Amorphous Nanocrystalline Cores

Industry: Amorphous Nanocrystalline Core

-

View More >>

View More >>

Amorphous Nanocrystalline Inductor Cores

Industry: Amorphous Nanocrystalline Core

-

View More >>

View More >>

CTS Series Terminal High Precision Amorphous Nanocrystalline Current Transformers

Industry: Current Transformer

-

View More >>

View More >>

Rectangular hysteresis loop Cores

Industry: Amorphous Nanocrystalline Core

-

View More >>

View More >>

High Linear Current Transformers

Industry: Current Transformer

-

View More >>

View More >>

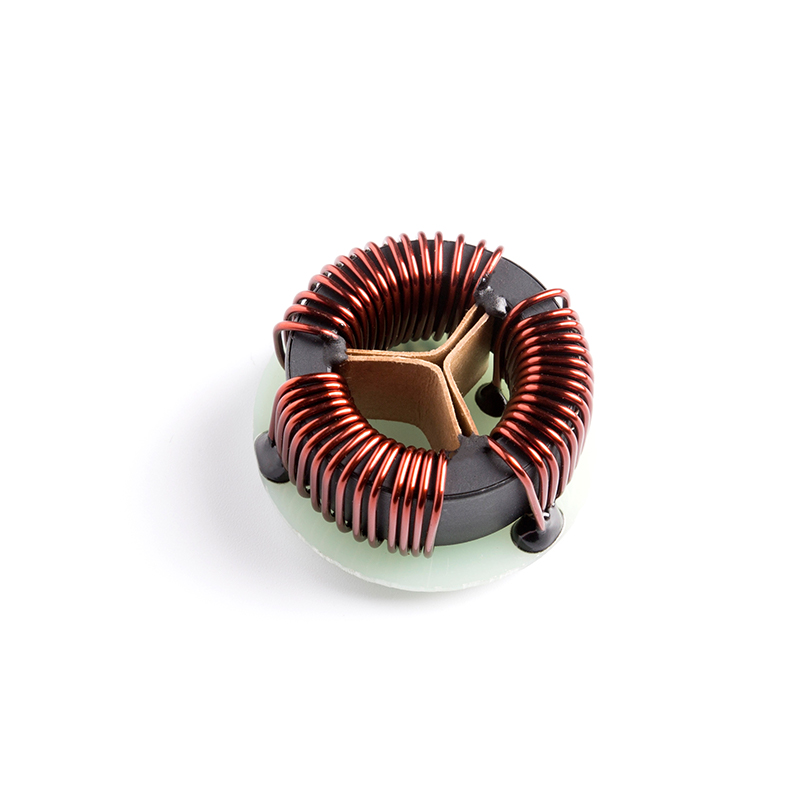

Common Mode Choke Amorphous Nanocrystalline Inductors

Industry: Amorphous Nanocrystalline Inductors

English

English 中文简体

中文简体 Deutsch

Deutsch 日本語

日本語