Amorphous Nanocrystalline Inductors offer advantages over traditional ferrite cores: High maximum permeability and low core loss. These magnetic properties enable significant size reduction of electronic components.

High Permeability

Amorphous alloy materials are created by rapid cooling a stream of molten metal. The process results in a material with short-range ordering and long-range disorder in its atomic arrangement and combination. This allows the material to be molded into shapes without forming magnetic domains, which would reduce the permeability.

The amorphous permeability of these cores is high, allowing them to operate at higher frequencies than traditional steel cores. This increases the power density of the core, reducing copper losses and improving the design efficiency of your circuits.

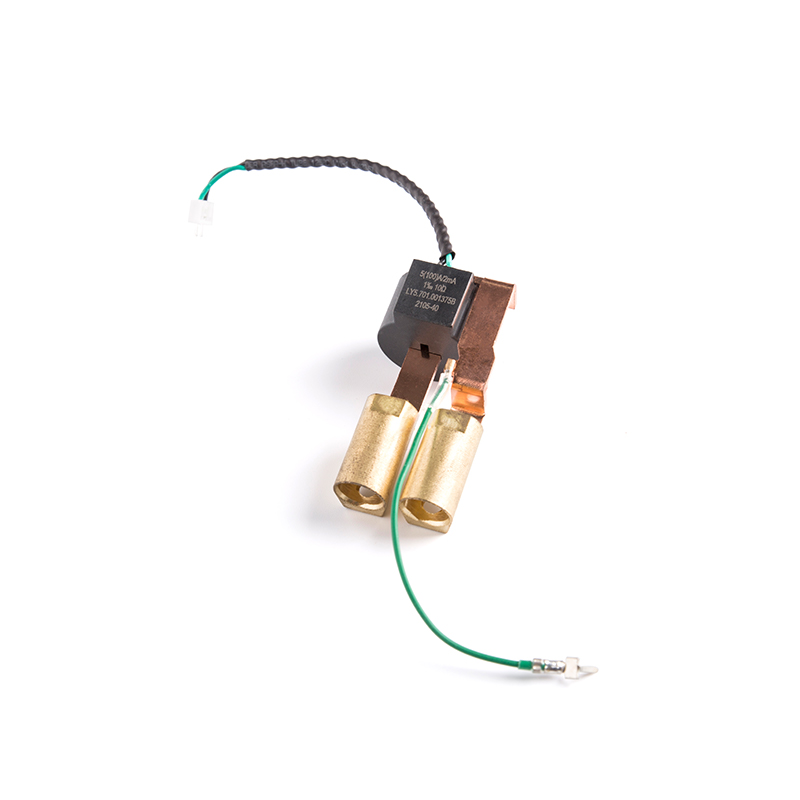

Iron based amorphous and nanocrystalline strips feature high saturation and permeability, making them ideal for common mode chokes in EMC filters. They are also used for output filter and current transformers in UPS, power supply and other power electronics. Other applications include air conditioners, ballasts and energy saving lights. These cores offer excellent frequency property, stable inductance versus DC bias current, varying DC bias stability and low loss.

High Saturation Flux Density

Amorphous nanocrystalline cores have higher saturation magnetic flux density than ferrite cores. This translates to less no-load loss, which in turn leads to higher efficiency. This increases power output with less energy loss, which also helps reduce operating costs over the life of a device.

Laminated iron based amorphous nanocrystalline strips can be used for all types of switch-mode power supply components including pulse transformers, control transformers, and amplifiers. They can operate in single-end, bridge or push-pull operating styles.

Heat treatment after compaction can eliminate internal strain that may lower permeability, coercivity and saturation magnetization. In addition, it can promote the crystallization of superparamagnetic nanocrystalline grains to increase permeability and coercivity. The resulting amorphous iron cores have a high permeability range of 120 to 1200u with low loss and Hc.

Low Loss

The high permeability of Amorphous Nanocrystalline metal offers size, core and labor savings compared to ferrite designs in power electronics. These advantages, along with the low losses and wide operating temperature range make Amorphous Nanocrystalline the ideal choice for power transformers and chokes in applications such as Inverters, UPS, ASD (Adjustable Speed Drive) and Switch-mode Power supplies (SMPS).

The effect of the mixing ratio of carbonyl iron powder and different heat treatment procedures on the magnetic properties of amorphous FeSiCrB alloy molding power inductors was investigated by an X-ray diffractometer and an SEM. The magnetic properties were characterized by the measurement of the initial permeability and the hysteresis loop of the toroidal bodies.

Miniaturization

Inductors are used in electronic circuits to store and release energy when needed. They are also used in many applications to reduce electromagnetic interference (EMI). Amorphous nanocrystalline cores provide better performance at high frequencies.

Unlike traditional steel cores that operate at lower flux saturation levels as the frequency increases, amorphous metal cores are much smaller and can be wound to higher currents without overheating. This allows you to use fewer turns for the same inductance and save on copper losses.

English

English 中文简体

中文简体 Deutsch

Deutsch 日本語

日本語

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>